A $5,000 bespoke suit isn’t just better fabric—it’s a personal pattern created exclusively for your asymmetrical body, requiring 3-5 fittings versus MTM’s 1-2. You’re buying hand-padded canvas that molds to you over decades, buttonholes that take 45 minutes each, and a relationship with a craftsman who remembers how your shoulder slope changes. The cost-per-wear drops to roughly $100 over its lifetime—making it, paradoxically, your least expensive garment with frequent use.

The $5000 Question

The $5000 Question

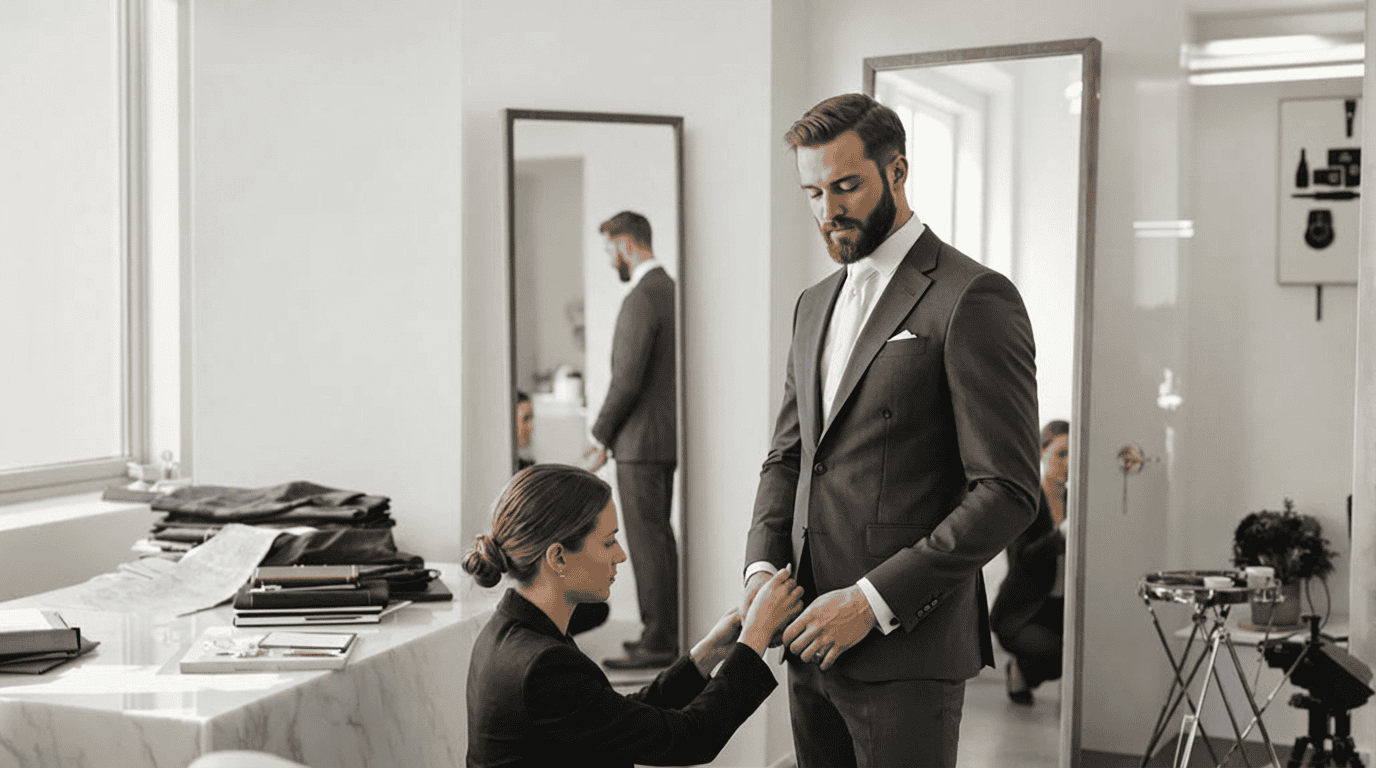

Why would any rational person spend $5,000 on a bespoke suit when a $2,000 altered garment hangs in the adjacent retail space? The answer lies not in vanity, but in construction fundamentals. You’re paying for a relationship—an expert’s eye evaluating your slope-shouldered stance, irregular proportions, that slight hitch in your walk. The bespoke tailoring value emerges through 3-5 fittings where patterns drafted exclusively for your body evolve, versus mere alterations to existing templates.

The tailoring quality difference reveals itself in hand-padded lapels that feel like cashmere against your neck, irregular stitches visible only when you flip the collar—proof of human craftsmanship. From 5,000 fabric choices to buttonholes shaped by calloused fingers rather than factory machines. Bespoke suits feature fully canvassed construction, unlike the glued or partially sewn interlining of cheaper alternatives. This dedication to quality over quantity manifests in every detail, ensuring each suit is a true reflection of your individuality.

And yet, the true luxury isn’t the suit itself but the ongoing service—years of tweaks, repairs, and adjustments as your body shifts, included without question.

Bespoke vs Made-to-Measure vs Off-Rack Altered

The visible differences between garment categories often mislead the uninitiated. You’ll see a $5,000 bespoke suit hanging beside a $2,000 altered off-rack option, and they appear similar—yet worlds apart in suit construction quality. The distinctions lie beneath surface aesthetics, embedded in processes invisible to casual observation.

True quality in tailoring hides in plain sight—beneath the fabric where craftsmanship speaks volumes that price tags merely whisper.

When comparing bespoke vs made-to-measure, you’re choosing between fundamentally different approaches:

- Pattern Creation: Bespoke starts from scratch with your unique body; MTM modifies existing templates.

- Fitting Sessions: Bespoke requires 2-4+ fittings; MTM typically needs 1-2.

- Customization Range: Bespoke offers 3,000+ fabric choices and unlimited details; MTM provides hundreds.

- Production Timeline: Bespoke demands 4-8 weeks minimum; MTM delivers in 2-4.

The bespoke suit cost reflects this labor-intensive process—handcrafting a garment that accommodates your posture, proportions, and movement patterns. This approach ensures that it can maximize your budget with effective tier allocation strategies for a truly personalized experience. Bespoke represents the absolute pinnacle of men’s tailoring with fully handcrafted construction that no other suit category can match. A higher investment, certainly, but one that pays dividends in fit and longevity.

Construction Methods: Full Canvas vs Fused vs Half Canvas

Every suit’s soul exists in its internal architecture, invisible to onlookers yet instantly felt by the wearer. Your $5,000 bespoke suit cost buys you full-canvas construction—a floating chest canvas hand-padded throughout, creating a garment that breathes, moves, and conforms to your body over years. It’s a custom suit investment that develops character with each wear.

The $2,000 alternative? Likely fused construction where interfacing adheres directly to the fabric, restricting movement and potentially bubbling after dry cleaning. Half-canvas represents the middle ground—canvas extending from shoulders to mid-torso, with fusing below.

Suit construction quality reveals itself in longevity: full-canvas withstands repeated alterations without compromise, while fused garments begin deteriorating almost immediately. You’re not just paying for prestige, but for architecture that shapes to you, endures decades, and paradoxically, becomes more comfortable—more you—with age. This investment mirrors the concept of ROI spending, as affluent couples often prioritize quality and longevity in their purchases.

Fabric Quality: Super Numbers Explained

Super numbers dominate fabric conversations, yet few understand what they actually signify. They measure fiber fineness—not overall quality—with higher numbers indicating softer fibers that, paradoxically, often wear faster. Your custom suit investment should balance luxury with longevity; the Super 100-130 range delivers that sweet spot where durability meets sophistication.

When evaluating suit construction quality, consider:

- Tier AA fabrics (Super 100-130) offer the best performance-to-luxury ratio

- Premium mills like VBC and Guabello define quality beyond mere numbers

- Higher super numbers (150+) sacrifice resilience for hand feel

- Daily wear suits benefit from lower super numbers, despite luxury allure

Is a custom suit worth it? Absolutely—but not because you’ve chased the highest super number. The true value emerges when fabric choice aligns with your actual lifestyle, not abstract prestige metrics. That’s where $5,000 bespoke wisdom trumps the $2,000 misconception.

Fit Precision: Pattern vs Alterations

While alterations can improve an existing garment, nothing rivals the anatomical precision of a pattern created exclusively for your body. You’re not simply adjusting what exists—you’re building from anatomical truth. Bespoke cutters map dozens of measurements, from shoulder angle to chest balance, creating a one-of-one blueprint never to be reused.

Made-to-measure offers a persuasive middle ground, modifying base blocks while preserving the designer’s aesthetic—faster production with admirable precision. But bespoke patterns capture your body’s idiosyncrasies through multiple fittings spanning weeks. The baste fitting, forward fitting, final fitting—each iteration refining the spatial relationship between fabric and form.

You’ll notice the difference in sleeve pitch, the way fabric drapes across asymmetrical shoulders, how the jacket rotates with your arm movement. Alterations adjust; patterns anticipate. It’s the difference between accommodation and anticipation, between fixing problems and preventing them entirely.

Detail Finishing: Hand vs Machine

Beyond the pattern lies the poetry—those painstaking handcrafted details that separate true bespoke from its machine-made counterparts. You’re not just paying for prestige; you’re investing in craftsmanship that reveals itself through microscopic evidence of human touch. Those seemingly minor finishing elements telegraph quality to discerning eyes.

Excellence lies not in perfection, but in the deliberate imperfections that reveal the human hand behind true craftsmanship.

When examining a garment’s pedigree, look for these handcrafted hallmarks:

- Buttonholes with slight irregularities and raised edges—imperfectly perfect signatures of artisanal precision

- Lapels with three-dimensional roll, created through laborious hand-padding that molds to your body over time

- Cross-pattern stitching at stress points, offering flexibility machine-made suits can’t replicate

- Armholes tailored specifically for your shoulder’s unique architecture

The difference feels revolutionary. A machine-stitched suit remains fundamentally static, while hand-finished garments evolve with your body. They’re living documents of craftsmanship that improve with wear rather than deteriorate—expensive, yes, but in the end offering value that transcends price.

What $5000 Bespoke Actually Delivers

The investment of $5000 in bespoke tailoring isn’t merely purchasing fabric and thread—it’s buying into a relationship with craftsmanship that begins long before scissors touch cloth. You’re paying for a skilled eye that spots your sloping left shoulder, the slight forward hunch in your posture, the asymmetry between hip heights—details no measurement tape captures.

Your pattern, created from scratch rather than modified from templates, becomes your sartorial fingerprint. Hand-padded canvassing creates that impossible-to-replicate softness, while those buttonholes—each requiring 45 minutes of meticulous handwork—serve as tiny signatures of authenticity.

But what truly separates bespoke isn’t just the finished product; it’s lifetime access to the mind that created it. When your body inevitably shifts, your tailor remembers your preferences, your history, your pattern. That $5000 suit might cost $100 per wear over its lifetime—and yet, with proper care and alterations, it becomes the least expensive garment you’ll ever own.

When Premium Is Worth It vs Unnecessary

Not every premium detail in tailoring justifies its expense—you’re paying for distinctions some will notice and many won’t. The truth? Bespoke’s value proposition isn’t universal but contextual, depending on your body, lifestyle, and priorities.

Consider investing in premium tailoring when:

- Your body deviates markedly from standard proportions—asymmetric shoulders, forward stance, or unusual height-to-weight ratio

- You’ll wear the garment 50+ times annually in high-visibility professional settings

- Your comfort sensitivity requires perfect drape and zero pressure points

- Movement patterns (frequent presentations, travel) demand construction that accommodates energetic posture

But skip the premium route if you’re seeking status symbols rather than functional improvements. A $2,000 made-to-measure suit, properly altered, will outperform an ill-chosen $5,000 bespoke piece. The canvas construction matters more than the buttonhole stitching—and yet, for some clients, those hand-sewn details become the signature elements they cherish daily.

Conclusion

Ultimately, what distinguishes true bespoke tailoring from its alternatives comes down to a fundamental philosophical choice about your relationship with clothing. It’s not simply a purchase but a cooperative creation—25-40 measurements translating into a garment that knows your body better than any mass-produced alternative ever could.

You’re investing in time as much as fabric—5-6 weeks of iterative improvement versus 2-4 weeks of minor adjustments. And yet, this temporal commitment yields something beyond mere fit: a garment that anticipates how you move, accommodates your asymmetries, and evolves through multiple fittings to become essentially yours.

The price differential—$3,000—buys you access to 5,000 fabric choices instead of a few hundred, hand-sewn construction throughout, and a pattern created exclusively for you that will never clothe another body. It’s clothing as identity rather than mere covering—expensive, yes, but impossible to replicate at any price point.